Drawer Durability and Strength Testing Machine: Enhancing Furniture Quality

May 23, 2024

Drawer Durability and Strength Testing Machine: Enhancing Furniture Quality

In the furniture manufacturing industry, product quality and durability are key concerns for consumers. The durability and strength of drawers, desks, cabinets, and wardrobes directly impact user experience and satisfaction. To ensure the quality of furniture, an efficient and precise testing tool is essential. The Drawer Slide Durability Cycle Testing Machine is such an indispensable device. This article will provide a detailed introduction to its functions, applications, and its significant role in furniture manufacturing.

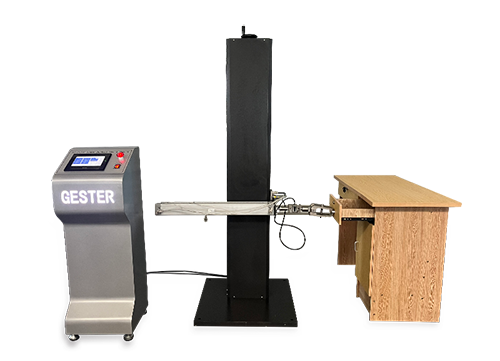

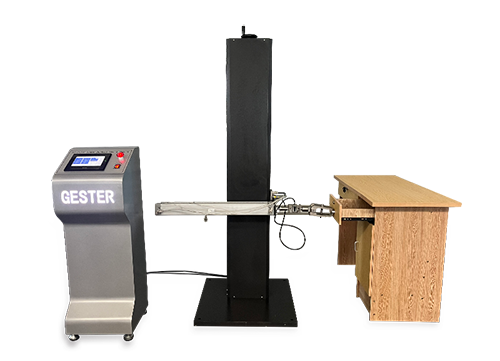

1. Product Overview

The Drawer Slide Durability Cycle Testing Machine is specifically designed to test the durability and strength of drawers, desks, cabinets, and wardrobes. It boasts powerful features, including cycling time control, constant travel control, frequency control, and test force display. Equipped with a PLC controller, the operation is intuitive and straightforward. It uses a precision pressure regulating valve to adjust the pressure, thereby changing the loading force value, and a high-precision force sensor to sense the force value immediately. These characteristics make this testing machine a crucial component in the furniture manufacturing process.

2. Core Functions

-Cycling Time Control: The machine can set and control cycling time, ensuring the accuracy and consistency of each test. This is particularly important for long-term durability testing, simulating the actual conditions of furniture over extended use.

-Constant Travel Control: With constant travel control, the machine can accurately simulate the movement range and manner of furniture components like drawers in real use, providing a more realistic reflection of their durability.

-Frequency Control: The device can adjust the testing frequency to meet the needs of different furniture components. High-frequency testing can quickly evaluate product durability, while low-frequency testing is suitable for simulating everyday use scenarios.

-Test Force Display: Real-time display of the test force value ensures the accuracy and reliability of test data. Through force value display, operators can adjust test parameters promptly, ensuring the testing process meets standard requirements.

3. Technical Advantages

-PLC Controller: The use of a PLC controller to manage the device's operations makes the operation simpler and more intuitive, while also enhancing the device's stability and reliability.

-Precision Pressure Regulating Valve: By adjusting the pressure through a precision pressure regulating valve, the loading force value can be flexibly adjusted to meet different testing needs. This not only improves testing accuracy but also broadens the device's applicability.

-High-Precision Force Sensor: The use of a high-precision force sensor for immediate force value sensing ensures that every test's data is accurate. This provides strong support for data analysis and product improvement.

4. Application Areas

The Drawer Durability Strength Testing Machine is widely used in various stages of the furniture manufacturing industry:

-Research and Development Stage: During new product development, durability and strength testing of samples can quickly identify design flaws, optimize product design, and improve product quality.

-Production Process: Random sampling and testing during the production process ensure that each batch of products meets quality standards, preventing substandard products from entering the market.

-Quality Inspection Stage: Comprehensive durability and strength testing before product shipment ensures that the product quality meets customer requirements, enhancing brand reputation.

5. Importance of Enhancing Furniture Quality

The durability and strength of furniture are not only related to the product's lifespan but also to user safety and experience. By using the Drawer Durability Cycle Testing Machine, furniture manufacturers can effectively improve product quality, reduce after-sales repair and replacement costs, and enhance market competitiveness. High-quality furniture products also help establish brand image, earning more consumer trust and favor.

6. Conclusion

The Drawer Durability Cycle Tester, as a professional testing device, offers advanced technology and powerful functions, providing a strong quality assurance tool for the furniture manufacturing industry. By conducting rigorous durability and strength tests on products, manufacturers can effectively enhance product quality, meet consumer demand for high-quality furniture, and achieve sustainable development.

Through this article, we hope to help furniture manufacturers better understand the Drawer Durability Cycle Tester and fully utilize this device in actual production, improving product quality, meeting market demand.