BS 5459-2: Specification for Performance Requirements and Tests for Office Chairs

Oct 13, 2025

BS 5459-2: Specification for Performance Requirements and Tests for Office Chairs

Office chairs are essential items in the workplace. To ensure employee health and comfort, many companies are increasingly focusing on the quality and safety of office seating.

BS5459-2 is a standard for office chairs established by the British Standards Institution. It provides consumers with clear quality benchmarks when purchasing office chairs, helping them avoid substandard products.

What is the BS5459-2

Specification for performance requirements and tests for office furniture, Office pedestal seating for use by persons weighing up to 150kg and for use up to 24 hours a day, including type-approval tests for individual components

BS 5459-2 Scope of Application

BS 5459 standards apply to office chairs, which typically feature height adjustment, swiveling, and other functions commonly found in various office settings.

1. BS 5459-2 Fore-and-after safety

Adjust the seat height, armrests, and other components; the locking mechanism must not engage. Determine the load value based on the chair's backrest tilt angle. One cycle consists of sequentially applying load to the seat load point and backrest load point, removing the load, then reapplying load to the appropriate front position of the seat. Repeat this cycle 500,000 times or until failure occurs.

2. BS 5459-2 Seat impact

Adjust the seat to its highest and lowest positions. Place foam padding on the seat. Drop an impactor freely from a height of 350mm onto the seat loading point and the position near the front edge, performing 5 impacts at each location.

Chair Seating Impact Durability Testing Machine GT-LB05

This Chair Seating Testing Machine applies to all types of chairs, with 2 functions of chair seating impact and seating durability test.

The purpose of this test is to evaluate the ability of the chair to withstand heavy and abusive impact forces on the seat and evaluate the ability of chairs to withstand fatigue stresses and wear caused by downward vertical force(s) on the seat.

3. BS 5459-2 Back impact

Using an impact hammer, secure the front legs of the chair. Drop the hammer from a vertical height of 330mm or at a 48° angle, striking the center of the outer top surface of the chair back. Perform 10 strikes.

4. BS 5459-2 Drop

Tilt the chair support at 10°, with one leg at the lowest point contacting the ground. Determine the lift height based on leg length (<200mm: 250mm; ≥200mm: 450mm). Drop the impactor 10 times onto each front and rear leg.

5. BS 5459-2 Side-to-side safety

Using a small seat loading pad, apply a 1200N force vertically downward alternately on both sides of the seat's lateral centerline, 50mm from the edge. Cycle 250,000 times or until failure. Safe failure is permitted after 120,000 cycles, with the count recorded.

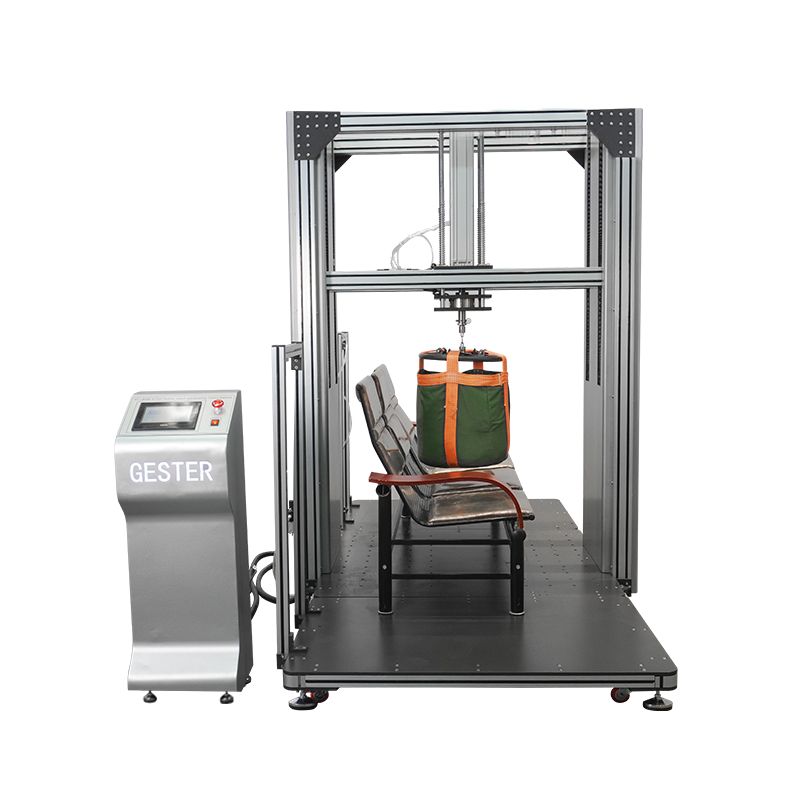

Chair Sideways Testing Machine GT-LB12

This Chair Sideways Testing Machine is used to simulate the loading condition of the chair in daily use, and test the lateral static load strength of the handrail.

The Chair Tester is equipped with two drive devices, and can be individually controlled separately to repeated load for the test point of the seat . Through different parameter settings, can do the test for different seats.

6. BS 5459-2 Stability tests

Adjust the state and position of different chair types, apply specified vertical and horizontal forces at designated points, and observe for tipping. Includes forward, lateral, and backward tipping tests, plus special tests for reclining and tilt-reclining chairs.

7. BS 5459-2 Durability of components

Perform lateral and downward static load tests and impact tests on armrests. Conduct corresponding cyclic loading tests on swivel mechanisms, seat height adjusters, footrests, control components, locking devices, etc., to simulate usage conditions and evaluate component durability.

Chair Armrest and Seat Tester GT-LB03S

Chair Armrest Testing Machine tests the strength and durability of the handrails, seats,or other parts by simulating the loading of the seats during routine use. The machine is equipped with two drive units, and can be individually controlled to repeatedly load the test points of the seat.

Through different parameter settings, the machine can complete the following types of test functions on the seat:

-

Armrests vertical static load test;

-

10°angle armrests durability test;

-

Seats front edge static load and durability test;

-

Vertical static load test on backrests;

-

Footrest static load and durability test;

-

Leg rest static load test;

-

Armrest upward static load test (need to be equipped with the weights);

-

Writing board vertical static load and durability test.